Menu ☰

Why Ventilation Matters

All roofing types benefit from proper ventilation, but metal roofing especially requires a good ventilation system. The main reason for this is to reduce condensation build-up on the underside of the metal panels. As a result of condensation in the air, without proper ventilation this condensation will build up between the metal panels and roofing substrate, which can result in mold and high humidity in attics.

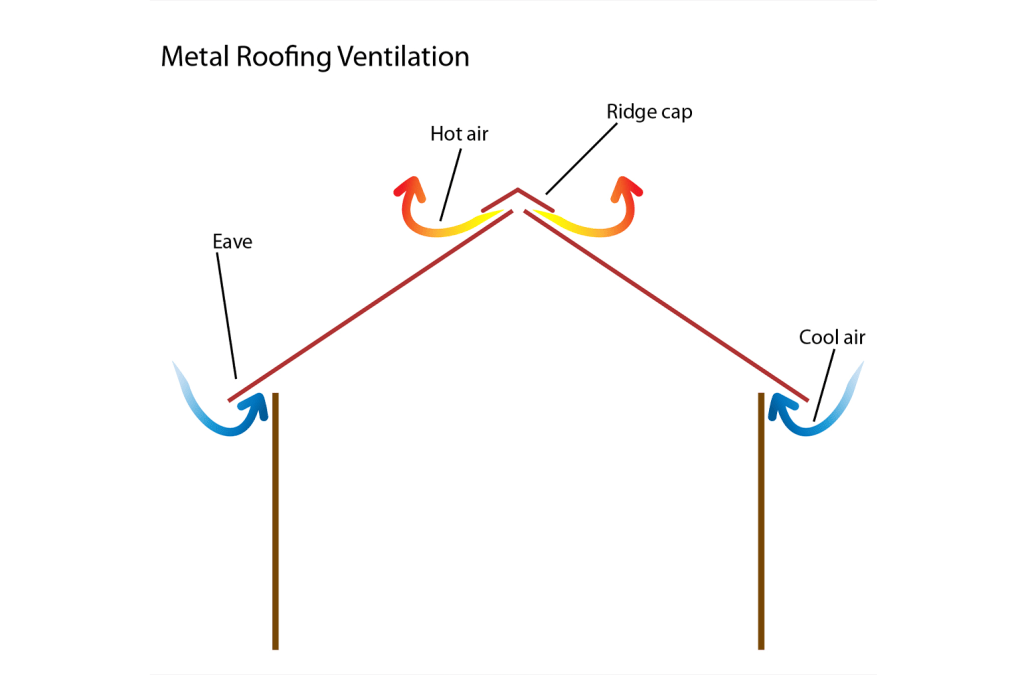

There are other reasons for why ventilation matters for metal roofing. A good ventilation system can significantly reduce home cooling costs. In many homes without good ventilation, hot air is trapped in the attic, making it difficult to cool the upper levels of a home. With good ventilation, this hot air is able to exit through the metal roof ridge vent, while cooler air is drawn at the eaves.

In colder climates, it is actually important to release hot air from the home,

in order to make sure that the metal panels remain evenly cold, especially after a snowfall. If hot air from the home is trapped under the metal roof, there will be portions of the roof that are warmer than others, causing

uneven snow melt, which can then refreeze as potentially dangerous and damaging ice dams.

A failure to provide adequate ventilation, as already mentioned, can

cause a build-up.

What Kinds of Vented Closures Are There?

Most ridge vent options are fairly similar in that they are a vented foam material with a high net free area. Net free area is simply the amount of space available for air to freely flow. Vented materials are typically made of an open cell material, meaning they are less dense and have the ability to allow airflow through the material, while also sealing the roof off from the elements, insects and other things that may come from outdoors.

It is important for the net free area at the ridge cap of the roof to be equal to or slightly less than the net free area at the eaves of the roof. This is important to create a positive airflow from the eaves and out trough the ridge. If the net free area at the ridge vent is larger than at the eaves, this can actually result in a negative airflow, and hot air will remain trapped under the roof.

Where the differences come in vented materials is of course in the quality of the material. It is important for vented materials to be weather and UV resistant, otherwise the material can degrade rather quickly once put under prolonged exposure to the outdoors, compromising the venting system.

If a metal roof does not use ventilation at the ridge and eaves of the roof, the other options would be gable roof vents, round gravity vents or power vents. While ventilation at the ridge and eave of the roof is a commonly used method for ventilation, these other methods are effective for any kind of roofing that does not provide air intake at the eave and exhaust at the ridge.

Venting For Vaulted or Cathedral Ceilings

When it comes to vaulted and cathedral ceilings with no attic space, some extra measures to ensure proper ventilation may need to be taken. In these cases, when insulation is installed under the roof decking, it is important to leave at least a 1″ gap between the insulation and the decking. If the insulation does not effectively allow for a space between it and the roof decking, baffles can be installed to run from the eave to the ridge, creating the necessary space to ensure clear and consistent airflow.

Now that you’ve been informed about ventilation systems for metal roofing, make sure that your metal roof is setup properly for good ventilation. This

will prolong the life of your metal roof, and offer other important benefits

to your home.