Menu ☰

What to Know About Galvanized Screws

The term “galvanized” refers to the application of a protective zinc coating, typically on iron or steel. Quality metal roofing screws will have some form of galvanizing in order to protect against the formation of red rust, which can result in failing screws and damage to the metal panels. There is however more than one method of galvanizing, and each has its benefits and drawbacks. The important thing to look for is that the galvanizing technique used on metal roofing screws is intended for exterior use, meaning it is able to withstand changes in temperature, humidity and even salinity in the air if near the coast.

Galvanizing Techniques

The most common galvanizing techniques are hot dipped galvanizing, zinc plating and mechanical galvanizing. Which method is used will depend on the size and shape of the item being galvanized, and also the intended purpose.

Hot Dipped Galvanizing

Hot dipped galvanizing is the technique of coating iron or steel in zinc by dipping the metal into a molten zinc bath at about 449°C or 840°F. This results in a heavy zinc coating that bonds to steel or iron, and is typically very durable and weather resistant. This method however does not result in a uniform coating, meaning there are thicker layers of zinc in some areas and thinner in others. For this reason, hot dipped galvanizing is typically reserved for larger, non-threaded items so as to not result in inconsistencies in the thread size.

Zinc Plating

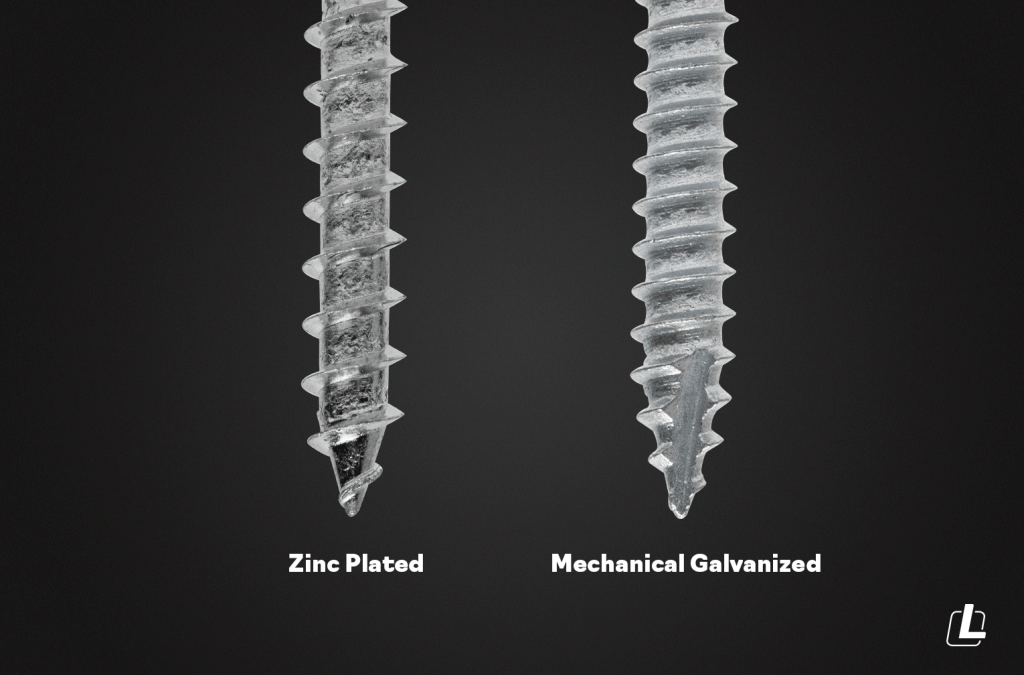

Zinc plating and another technique known as electro-plating are very similar. Both use acid baths to clean the item being galvanized and to remove any oxidants that can cause corrosion from underneath the coating. After being rinsed, the item is racked and placed into a plating solution. This method of galvanizing results in a zinc layer of up to 1 mil in thickness. Zinc plating is best for interior use, because it is not as durable as other methods.

Mechanical Galvanizing

Mechanical galvanizing is accomplished by combining glass beads, plated chemicals, zinc powder, water and the fasteners in a rotary barrel. Mechanical galvanizing applies up to a 4 mil thick layer of zinc at higher psi than other galvanizing techniques, making it the most suitable for screws and other kinds of fasteners intended for exterior use. While mechanical galvanizing gives a dull finish, meaning it isn’t as aesthetically pleasing as the finish of other galvanizing techniques, it is the best galvanizing solution for smaller items that will be exposed to harsh conditions. Rotary Barrel. The barrel is then spun, causing the plating chemicals, zinc powder and water to combine, while the glass beads hammer the zinc solution onto the fasteners. The

force of the glass beads hammering the solution onto the fasteners has a welding effect and also results in a more uniform zinc plating than hot

dipped galvanizing.